BioStar Organics

BioStar Organics utilizes waste management practices and methodologies to convert waste into energy and waste into organic fertilizer.

SuperSix™ Organic Fertilizer

BioStar Organics owns two proprietary, patented technologies for producing high-nitrogen OMRI certified organic fertilizer from animal manure.

SuperSix™ Organic Nitrogen Fertilizer

The first true 6% plant available N organic certified and OMRI Listed organic nitrogen fertilizer. SuperSix™ is a honey-colored, translucent, liquid-organic, ammoniacal, nitrogen-fertilizer that will flow freely through irrigation/fertigation delivery systems as well as drip-tape delivery fertigation systems. It will not clog, has a non-offensive odor, and is concentrated. SuperSix™ meets the NOP requirements for use in organic farming and is an OMRI listed product. By concentrating, we reduce water content in the liquid to decrease our shipping costs. SuperSix™ is the best in class-organic liquid-fertilizer for certified organic growers. SuperSix™ is easy to handle, will not settle, and has a very low freezing temperature. SuperSix™ is free of pathogens and harmful bacteria because our high-temperature anaerobic digestion process destroys pathogens in manure. It is a revolutionary fertilizer that delivers great results and higher crop yields.

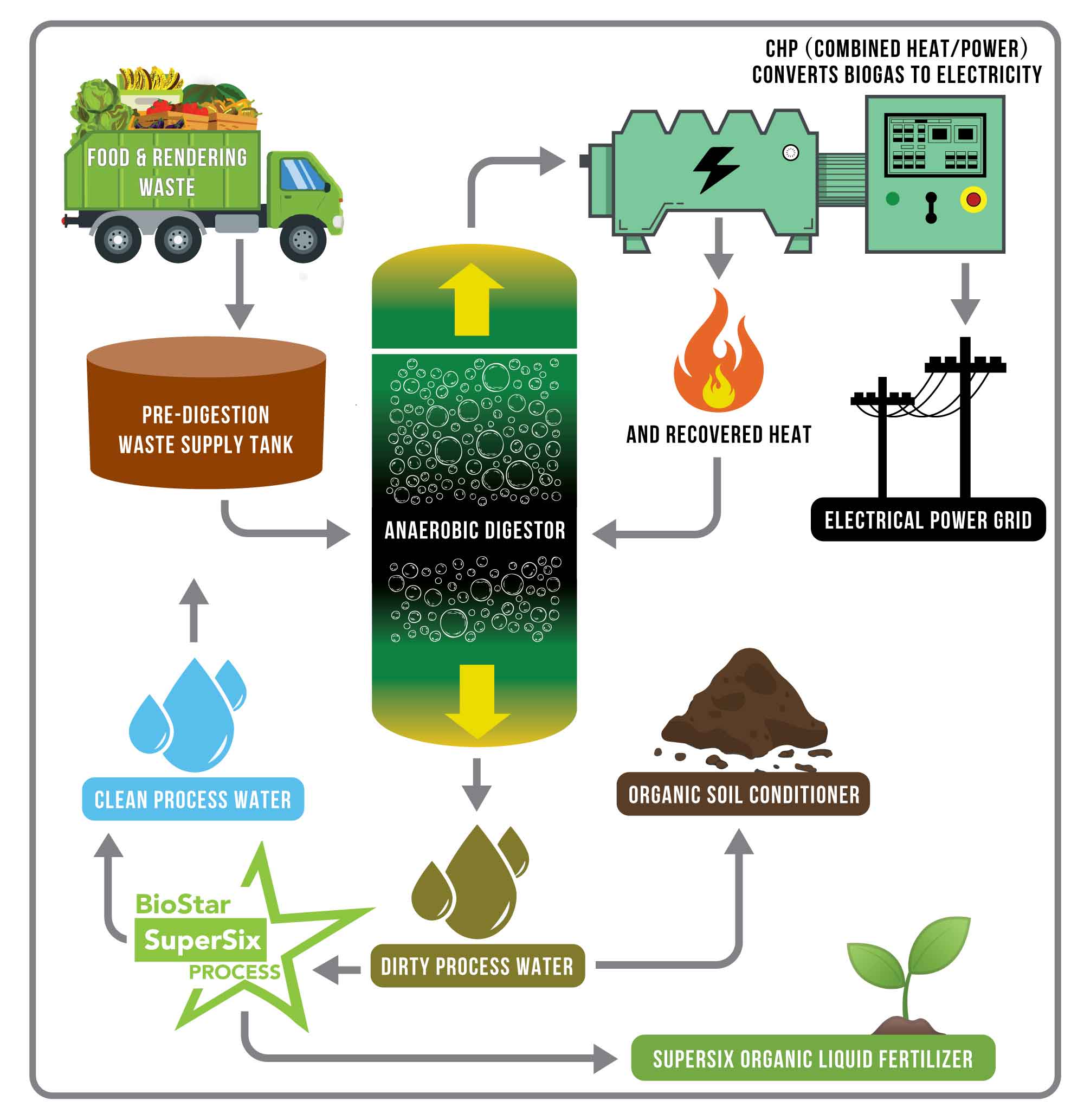

BioStar’s patent number, US 2013/0283872, is for the concentration of nitrogen into a liquid fertilizer product derived from the effluent from anaerobic digestion. Nitrogen is a compound of ammonia produced by anaerobic digestion, which drives the major value of the fertilizer component of SuperSix™. Clean water is also a by-product of BioStar’s nutrient recovery system, reducing water pollution in the surrounding ecosystem.

Product Features

- Plant-available no matter the conditions

- SuperSix™ is the only OMRI-approved, liquid-organic source of 100% plant available fertilizer on the market

- Over 90% ammoniacal, the most plant available N organic fertilizer in the industry today.

- Performs during low ambient and soil temperatures of the early season

- Easy-to-use

- Particulate-free

- Flows easily and cleanly through drip lines and sprayers without clogging

- Food safe

- OMRI listed and safe for use on fruits and vegetables within days of harvest

- Both heat-treated and ultra-filtered to ensure safety and quality

Waste-to-Energy

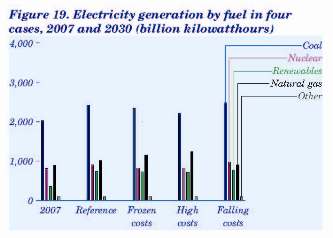

Waste-to-energy is the process of creating energy in the form of electricity or heat from a waste source. WtE is a form of energy recovery. Most WtE processes produce energy through combustion, which contributes to greenhouse gas emissions, whereby, the BioStar anaerobic digestion waste to energy process does not. WtE projects produce a combustible fuel commodity, such as methane, methanol, ethanol or synthetic fuels.

Anaerobic Digestion

Anaerobic digestion is a century’s old process of converting organic matter into methane and ammonia. Generally performed in lagoons or tanks, anaerobic digestion is the biological treatment of liquid waste using bacteria in the absence of air to promote the decomposition of organic solids. Viable feedstock materials typically include animal manure, food waste, and other organic wastes. The anaerobic digestion process works similar to an animal’s natural digestive system, where enzymes break down organic matter in the absence of oxygen. Methane and ammonia are two primary by-products of the process. The methane biogas RNG (Renewable Natural Gas) is used for fuel or, electricity. The resultant nutrient-rich liquid can be pumped onto fields as fertilizer. The methane, a.k.a. biogas, can be used as transportation fuel, natural gas heating, or running through a CHP to generate electricity which can be injected in the interstate pipeline and sold to local utilities.

FEATURED PROJECT

San Bernardino Waste-to-Energy - San Bernardino, CA - Learn More

Waste-to-Fertilizer

Feedstock Management

The USDA estimates that more than 335 million tons of “dry matter” waste (the portion of the waste remaining after water is removed) are produced annually on CAFO (Confined Animal Feeding Operations) farms in the United States, representing almost a third of the total municipal and industrial waste produced every year. Animal waste runoff can impair surface water and groundwater which can affect water quality, public health. It can produce odors, the loss of wildlife habitat, and the depletion of groundwater.

Agricultural pollution (such as sediment and nutrient runoff) is a prime contributor to the nation's water quality problems. This is highlighted by a PBS documentary on poison waters from chicken farms killing the Chesapeake Bay. In Arkansas, the nation's leading poultry producing state, 90 percent of the surface water bodies (statewide) sampled recently by the Arkansas Department of Pollution Control and Ecology contained fecal coliform counts in excess of the primary contact standards. The waste management of the poultry farms in the state of Arkansas has caused the Oklahoma Attorney General to file suit. While BioStar is neutral in the dispute, the undisputed fact remains that agriculture manure management is a problem in the United States.

BioStar Organics, LLP (BioStar) is in business to process CAFO waste as a feedstock to produce organic fertilizer and for energy generation. BioStar has two patent-pending processes for converting organic material, including livestock manure and food waste into a final end product SuperSix™ Liquid Organic Fertilizer is the first pathogen-free, food-safe liquid organic fertilizer listed by OMRI (Organic Materials Review Institute) for use on food for human consumption, lawns, and golf courses.

FEATURED PROJECT

Majestics Crossing Dairy – Sheboygan, WI - Learn More

Manure Drying

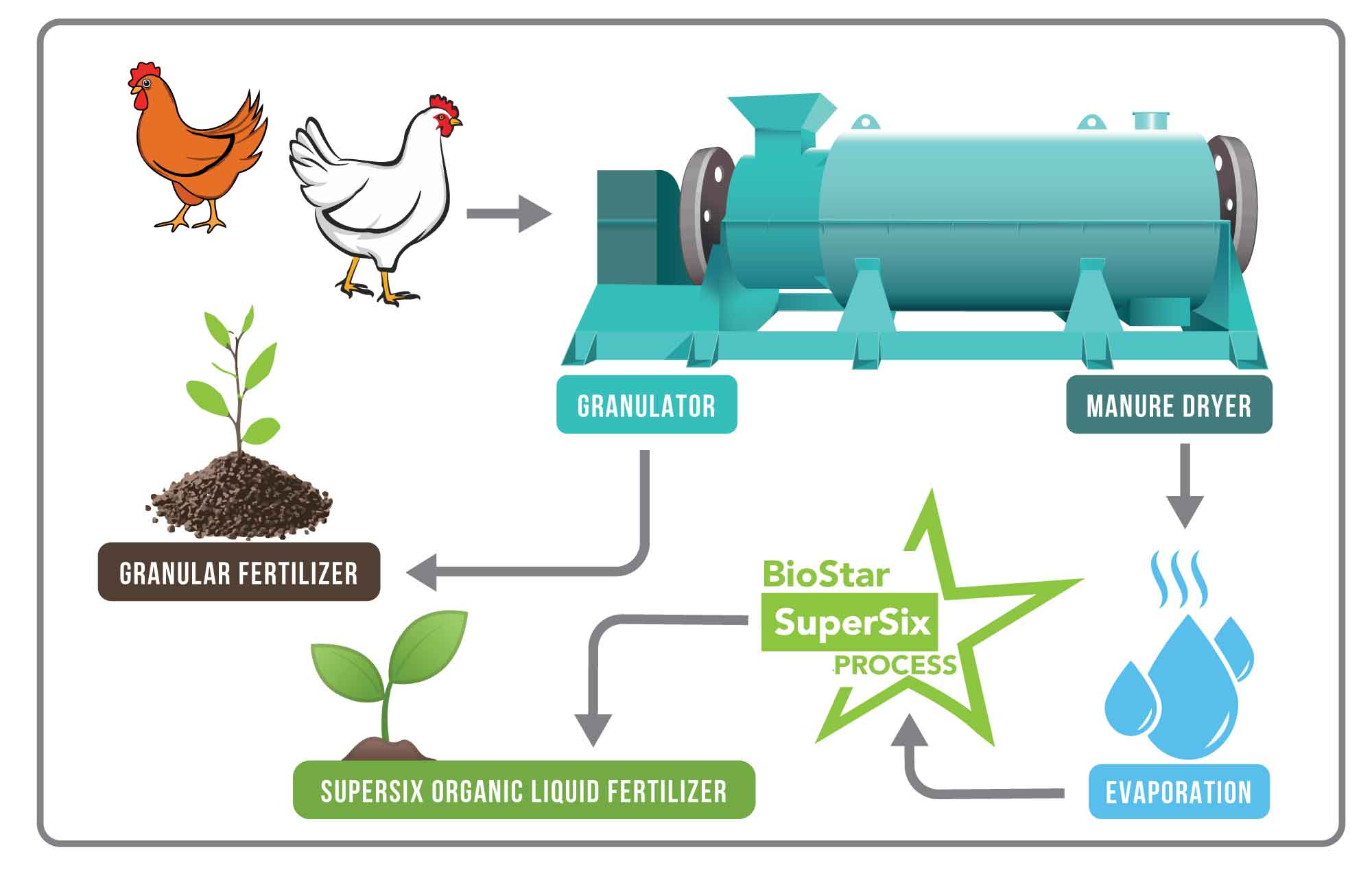

BioStar’s second patent-pending,10,023,501 is to concentrate the nitrogen into OMRI listed SuperSix™ liquid fertilizer from Perfect Blend’s patented manure drying process. BioStar captures the moisture from the drying process, cleans and concentrates the nitrogen such that granular fertilizer and SuperSix™ are the only two by-products of the process.

FEATURED PROJECT

Perfect Blend Plant – Othello, WA - Learn More