Waste-to-Fertilizer

Feedstock Management

The USDA estimates that more than 335 million tons of “dry matter” waste (the portion of the waste remaining after water is removed) are produced annually on CAFO (Confined Animal Feeding Operations) farms in the United States, representing almost a third of the total municipal and industrial waste produced every year. Animal waste runoff can impair surface water and groundwater which can affect water quality, public health. It can produce odors, the loss of wildlife habitat, and the depletion of groundwater.

Agricultural pollution (such as sediment and nutrient runoff) is a prime contributor to the nation's water quality problems. This is highlighted by a PBS documentary on poison waters from chicken farms killing the Chesapeake Bay. In Arkansas, the nation's leading poultry producing state, 90 percent of the surface water bodies (statewide) sampled recently by the Arkansas Department of Pollution Control and Ecology contained fecal coliform counts in excess of the primary contact standards. The waste management of the poultry farms in the state of Arkansas has caused the Oklahoma Attorney General to file suit. While BioStar is neutral in the dispute, the undisputed fact remains that agriculture manure management is a problem in the United States.

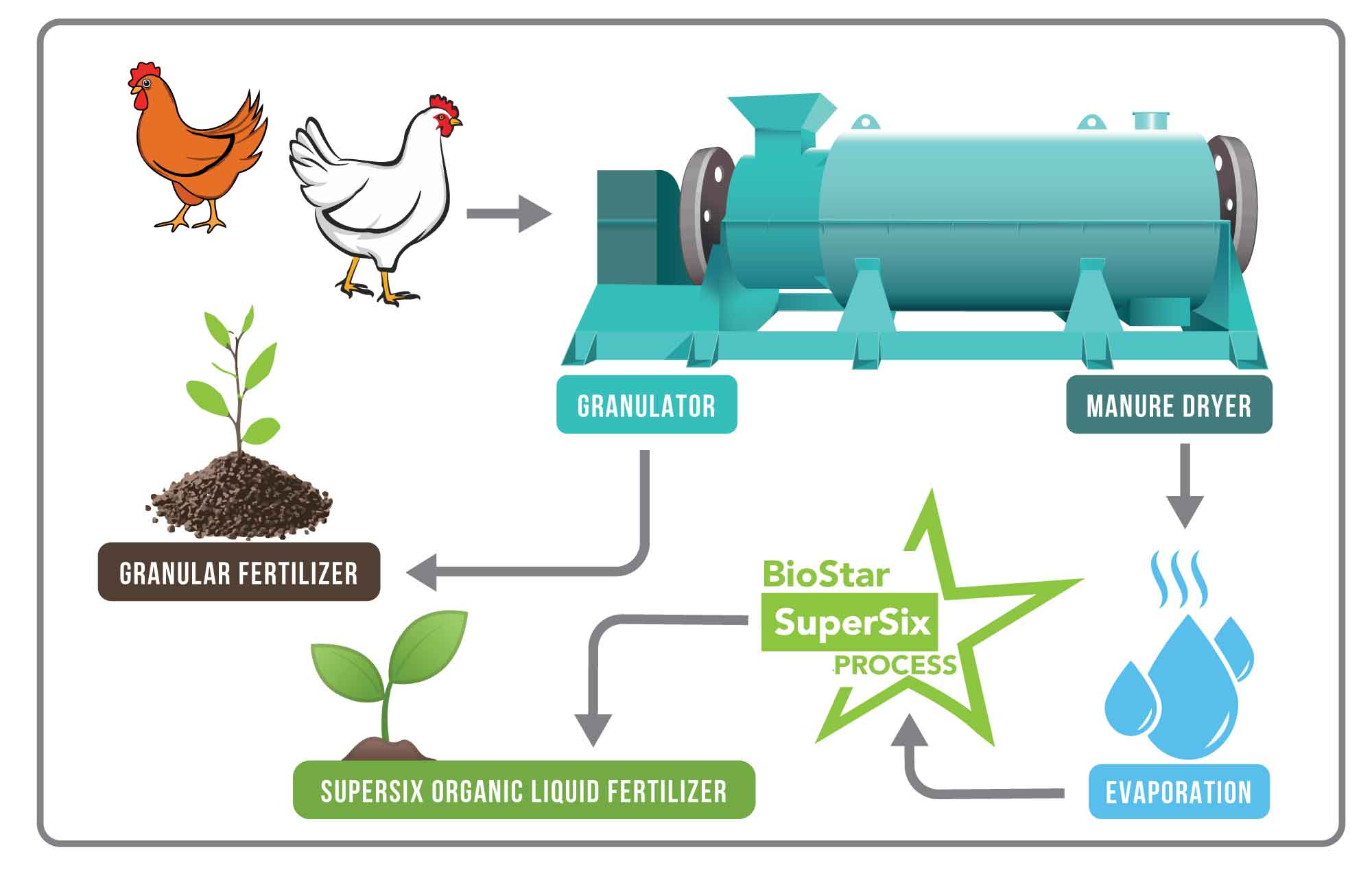

BioStar Organics, LLP (BioStar) is in business to process CAFO waste as a feedstock to produce organic fertilizer and for energy generation. BioStar has two patent-pending processes for converting organic material, including livestock manure and food waste into a final end product SuperSix™ Liquid Organic Fertilizer is the first pathogen-free, food-safe liquid organic fertilizer listed by OMRI (Organic Materials Review Institute) for use on food for human consumption, lawns, and golf courses.

BioStar's Proprietary Waste-to-Fertilizer Process Video

FEATURED PROJECT

Majestic Crossing Dairy – Sheboygan, WI - Learn More

Manure Drying

BioStar’s second patent-pending,10,023,501 is to concentrate the nitrogen into OMRI listed SuperSix™ liquid fertilizer from Perfect Blend’s patented manure drying process. BioStar captures the moisture from the drying process, cleans and concentrates the nitrogen such that granular fertilizer and SuperSix™ are the only two by-products of the process.

FEATURED PROJECT

Perfect Blend Plant – Othello, WA - Learn More