Visit Project Page

N5853 Meadowlark Rd, Sheboygan Falls, WI 53085

Farming

Developer

Visit Project Page

N5853 Meadowlark Rd, Sheboygan Falls, WI 53085

Farming

Developer

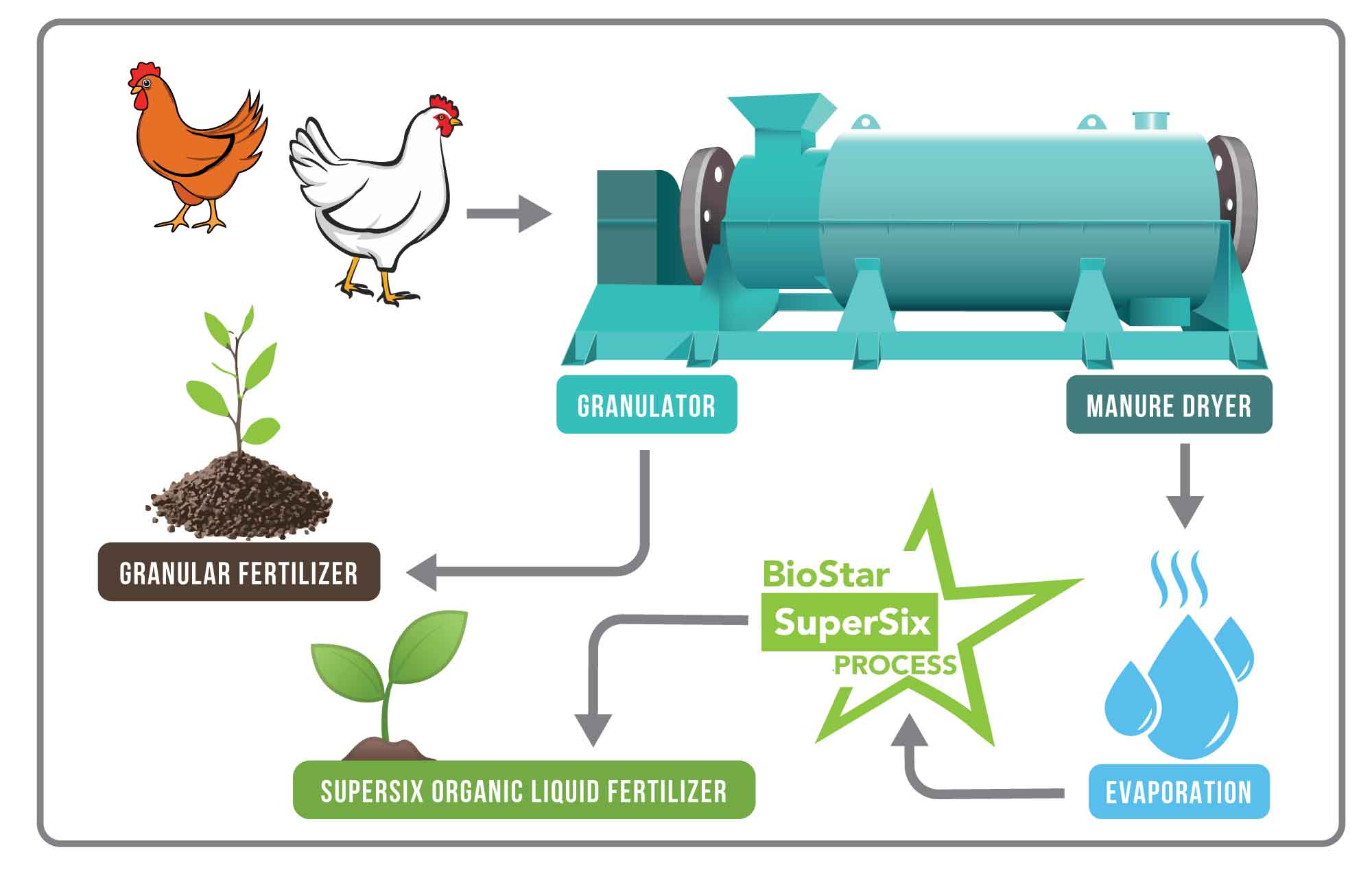

BioStar and its equipment suppliers have extensive experience in handling and processing dairy manure. Dairy waste is more difficult to process than other waste since it contains high amounts of fiber and a lower concentration of ammonia – making a fertilizer plant more profitable due to the high volumes of waste.

BioStar partnered with Majestic Crossings Dairy in Sheboygan Falls, WI to successfully run a solid-liquid separation system that produces the same centrifuge system to remove the fiber, separate the suspended solids and reverse osmosis, which separates the dissolved solids. BioStar’s patented process produces the secret sauce, SuperSix™ Organic Liquid Fertilizer. During the final evaporation step, the system removes water and concentrates the Nitrogen, resulting in the final product.

Not only does SuperSix™ meet National Organic Program (NOP) requirements for farming, it’s easy to handle, will not settle and has a very low freezing temperature. Additionally, manure pathogens and harmful bacteria are destroyed during the anaerobic digestion process, resulting in an OMRI Listed product that’s safe to use on fruits and vegetables.

HOW IT WORKS

Visit Project Page

6479 Church St, Riverdale, GA 30274, USA

Education

Installer

Visit Project Page

6479 Church St, Riverdale, GA 30274, USA

Education

Installer

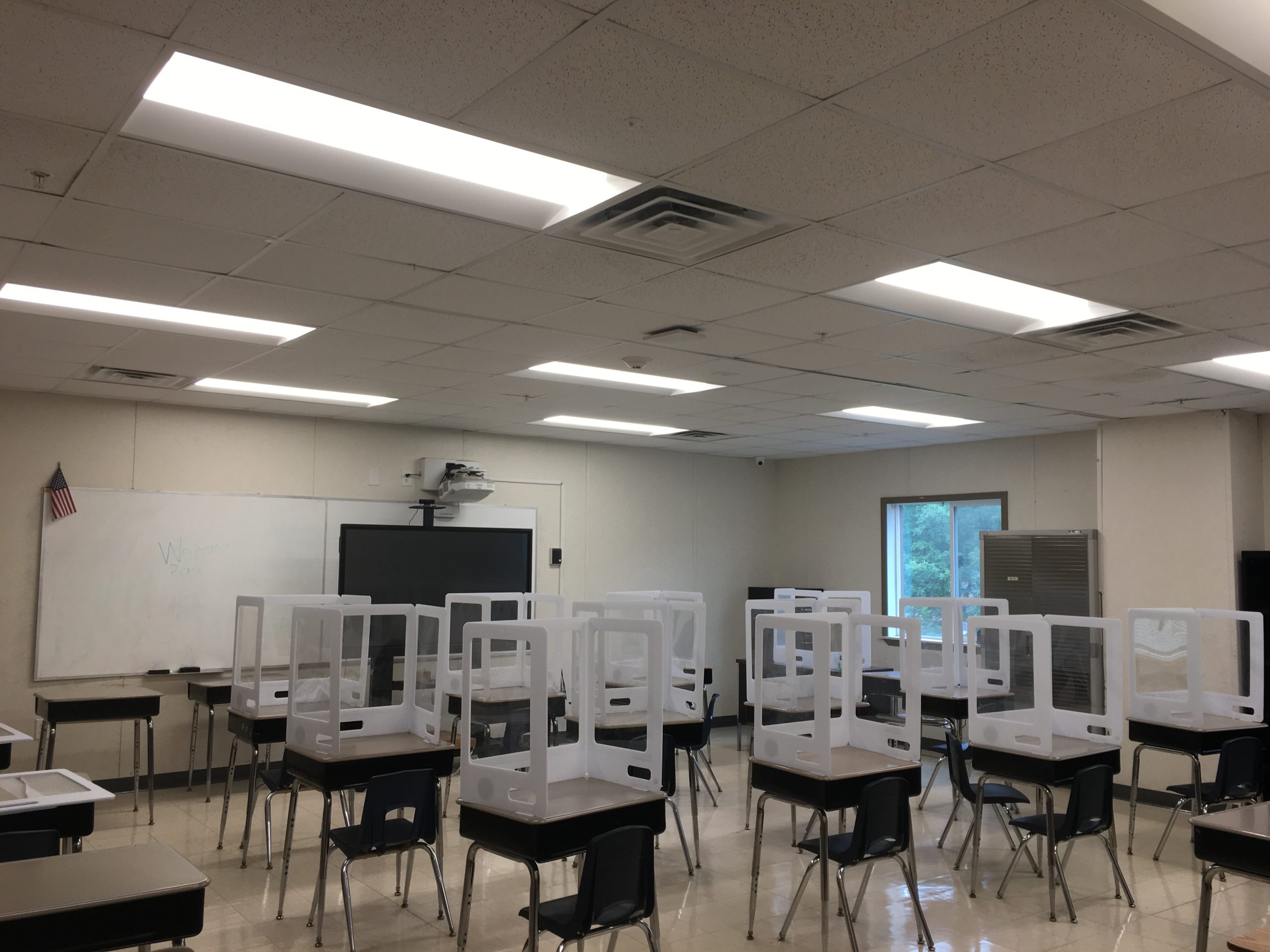

Du Bois Integrity Academy has leveraged a partnership between BioStar Renewables and Charter School Energy to enhance and upgrade the school by adding a new layer of protection in the building’s HVAC system. The project is expected to have considerable annual energy savings for the school, while improving the interior and exterior lighting, adding in smart building controls to maximize energy savings and installing an Indoor Air Quality system that actively combats coronavirus, bacteria, mold and more.

Visit Project Page

Norman, OK

Municipal

Developer

Visit Project Page

Norman, OK

Municipal

Developer

The City of Norman & BioStar Renewables have achieved interconnection and are producing renewable electricity at the city’s new solar project which serves the Vernon Campbell Water Treatment Plant and Water Reclamation Facility in Norman, Oklahoma. The 2.27 MW solar project is expected to produce more than 3,000,000 kWh of electricity each year and will displace over 2,126 metric tons of CO2 equivalent emissions per year, the equivalent of providing 438 homes with electricity or 271,000 gallons of gasoline consumed for an entire year. The clean energy generated by the solar arrays will reduce the annual kWh required from the local utility company by approximately 30%.

BioStar developed the project, as well as providing the engineering, procurement and construction (EPC) services, as well as ongoing operations and maintenance (O&M) services. E Light Electric partnered with BioStar and played a pivotal role in delivering the project. Implementation of these solar arrays will set the city on a path toward achieving their Net-Zero Carbon goal across city buildings, and marks the beginning of a transition to more balanced energy mixture.

City of Norman, OK Water Reclamation Solar Facility -2 from BioStar Renewables

Aerial view of water treatment facility.

Aerial view of water treatment facility.

Visit Project Page

2586 Shenandoah Way, San Bernardino, CA 92407, USA

Owner / Operator

Visit Project Page

2586 Shenandoah Way, San Bernardino, CA 92407, USA

Owner / Operator

Turning Food Waste Into Renewable Energy

California’s SB 1383 is a bill that requires a 75% reduction (up to 27 million tons) in Organic Landfill Waste by 2025. Enforcement of the new law started in 2022, meaning municipalities and waste haulers started facing fines for landfilling organic waste earlier this year. This is where BioStar comes in. Using anaerobic digestion, the San Bernardino Waste-to-Energy project converts pre-consumer food waste into renewable resources that not only diminish solid landfill waste, but reduce organizations’ carbon footprint, and help achieve increasing sustainability goals. Recovered resources such as clean industrial water, organic liquid fertilizer, biogas and electricity will aid in meeting California’s requirements. BioStar’s patented backend process creates nutrient-rich, carbon-based, organic, food-grade fertilizer, all while generating renewable power, which is delivered to the Southern California Edison power grid via a utility interconnection. Diverted waste results in significant cost savings and reduced tipping fees for haulers, food waste generators and municipalities. BioStar Renewables manages and facilitates all aspects of the process – from collection and pre-processing to digestion and generation – spearheading long-term agreements that make achieving sustainability goals a seamless reality.

HOW IT WORKS

Beginning in 2022, the San Bernardino Waste-to-Energy project will divert 93,850 tons of pre-consumer food waste from the Coachella and Lambs Canyon landfills each year. As a result, 85,000 gallons per day or 31,025,000 gallons of food waste per year will create:

![]()

21,637,200 kWh of Electricity

per year

![]()

849,000 Gallons of SuperSix™ Fertilizer

per year

![]()

18,250 Tons of Compostable Fiber

per year

![]()

19,876,800 Gallons of Clean Water

Industrial reuse per year

![]()

Greenhouse Gas Emission reductions equivalent to:

![]()

38,061,903 Miles

Avg. passenger vehicle

![]()

1,725,431 Gallons

of gasoline consumed

![]()

2,984 Homes’

Energy per year

![]()

16,965,573 Pounds

of coal burned

*Source: EPA’s Greenhouse Gas Equivalencies Calculator.

PROJECT DETAILS

The City of San Bernardino is home to ~217,000 people, while San Bernardino County has a population of ~ 2.2-million people. The amount of food waste generated is significant and has put stress on the traditional methods of disposal such as landfills, composting facilities, and municipal solid waste facilities. With recent studies indicating that approximately 36-million tons of food waste goes un-utilized and only about 3% of this food waste volume is recovered – the project will prove beneficial by creating baseload renewable energy, nutrient and carbon recovery, as well as generating valuable solids which can be composted. With the passing and now enforcement of California’s new landfill diversion law, SB 1383, waste-to-energy facilities will become increasingly important to meeting the state’s goals. The goal of the San Bernardino Waste-to-Energy project is to provide a valuable facility for resource recovery, energy production, and financial benefits to the region by turning pre-consumer food waste into feedstock, ultimately producing beneficial products and materials. The facility consists of three digesters, with a total liquid capacity of approximately 1.8-million gallons and additional space available for the expansion of future digesters. The methane rich biogas is fed through two, 1.3 MW engines, ultimately creating caseload renewable electricity that will provide stability to the local power grid. The exhaust from the engines is treated to meet California air quality standards as well as noise restriction requirements. Heat is recovered from the engines and recycled to maintain optimum temperatures in the digesters to maximize efficient operational conditions. Finally, the project obtained a 2.6MW utility grid interconnect. The project is supported by a 20-year power purchase agreement (PPA) with Southern California Edison. The site layout is designed to handle additional feedstocks to further increase volume and revenue, while sending excess biogas to heat recovery or to the flare. The below graphics outline the project’s inputs and outputs.

PROJECT PHOTOS

[rev_slider alias=”oes”][/rev_slider]

PROJECT SITE

FAQs

What is anaerobic digestion? Expand

Anaerobic digestion is a collection of processes by which microorganisms break down biodegradable material in the absence of oxygen. The process is used for industrial or domestic purposes to manage waste and/or to produce fuels. Typically, three things come out of an anaerobic digester for beneficial reuse: Biogas (which can be turned into electricity and heat, or fuel), Solid Fertilizer (from the digestate, the materials after they have been digested) and Liquid Fertilizer (from the centrate, the liquids after they have been digested).

What can be put in an anaerobic digestor? Expand

Many types of organic material can be used as feedstock to produce biogas. Animal manures, wastewater solids, food scraps, restaurant fats, oils, and greases, and by-products from food and beverage production are some commonly digested materials. An anaerobic digester may be built for a single material or a combination of them. However, the feedstocks must be properly controlled to ensure that the system remains healthy and functioning.

Why divert waste to an anaerobic digestor? Expand

Most municipalities are investing in ways to divert materials from landfills. This is usually due to reduced landfill space and/or recycling goals. Wastewater treatment facilities offer the opportunity to divert large amounts of food waste, one of the largest waste streams still going to landfills.

Is diverting waste to an anaerobic digestor a responsible method of disposal? Expand

Food waste is one of the single largest constituent of municipal solid waste stream. In a typical landfill, food waste is one of the largest incoming waste streams and responsible for the generation of high amounts of methane. Diversion of food waste from landfills can provide significant contribution towards climate change mitigation, apart from generating revenues and creating employment opportunities.

Why is it important to divert food waste from landfills? Expand

Reducing the amount of food wasted has significant economic, social & environmental benefits:

Environmental Benefits

There are many resources needed to grow food, including water, fertilizers, pesticides, and energy. By wasting food, you are also wasting the resources that when into growing it. Additionally, 13 percent of greenhouse gases in the United States are associated with growing, manufacturing, transporting, and disposing of food. By reducing the amount of food wasted, we can reduce greenhouse gas emissions.

Economic Benefits

Lower disposal costs by decreasing the amount of food wasted, businesses pay less to dispose of their trash. By making strides to prevent food waste, businesses can reduce costs by purchasing only the food that will be used, or decreasing improperly prepared foods. Additionally, reducing food waste can increase staff efficiency and reduce energy and labor associated with disposing of food. Finally, by donating wholesome and edible food to food banks or food rescue organizations, businesses can claim tax benefits as well as feed those in need.

Social Benefits

An estimated 50 million Americans do not have access to enough food. Organizations can donate safe and healthy food to a food bank or food rescue organization and both reduce food sent to landfills and feed people in need.

How does food waste impact our air quality? Expand

When food is disposed in a landfill it rots and becomes a significant source of methane – a potent greenhouse gas with 21 times the global warming potential of carbon dioxide. Landfills are a major source of human related methane in the United States, accounting for more than 20 percent of all methane emissions.

What kinds of businesses can divert food waste to an anaerobic digestor? Expand

A wide variety of businesses can contribute foodwaste to an anaerobic digestor including grocery stores, restaurants, commercial food processing entities and industrial food processing companies.

PARTNERING ORGANIZATIONS

Contact us if you’d like to become a partner!

Visit Project Page

Farming

Developer

Visit Project Page

Farming

Developer

Visit Project Page

4442 Carbon Canyon Road, Brea, CA 92823

Commercial Real Estate

700

Installer

Visit Project Page

4442 Carbon Canyon Road, Brea, CA 92823

Commercial Real Estate

700

Installer

The purpose of the proposed solar power facility is to supplement the current power generated by Inland Empire Utilities Agency (IEUA) from biogas and to reduce peak loads from Southern California Edison (SCE) with electricity supplied from the solar photovoltaic system. The proposed solar power facility (SPF) is designed to generate up to one (1) megawatt of electricity from the photovoltaic system and the SPF is proposed to be installed on the CCWRF project site. The proposed project consists of installing the SPF panels at one of several open location on the CCWRF site and connecting these panels to the SCE electrical grid which is located adjacent to the project site. All of the above proposed activities will occur within the footprint of existing disturbed areas at the CCWRF site.

Visit Project Page

Ontario, CA

Commercial Real Estate

780

Installer

Visit Project Page

Ontario, CA

Commercial Real Estate

780

Installer

Visit Project Page

11175 E. 55th Ave., Denver, CO 80239

Commercial Real Estate

10

Installer

Visit Project Page

11175 E. 55th Ave., Denver, CO 80239

Commercial Real Estate

10

Installer

Visit Project Page

Oxnard, CA

Government

180

Installer

Visit Project Page

Oxnard, CA

Government

180

Installer

Visit Project Page

Sangre De Cristo Re-22, Monte Vista, CO 81144

Utility

20000

Installer

Visit Project Page

Sangre De Cristo Re-22, Monte Vista, CO 81144

Utility

20000

Installer

Visit Project Page

Air Force Academy, CO

Government

5000

Installer

Visit Project Page

Air Force Academy, CO

Government

5000

Installer

18,888 solar panels were installed on this 30-acre site with a flat tracker system to produce 6 MW DC of renewable energy. Additionally, 9,400 total linear feet of medium and DC voltage cabling were installed underground with precise spacing in the trench through the use of prefabricated components. This system is designed to meet the U.S. Air Force Academy’s stringent engineering design standards. This project was funded by the American Recovery and Reinvestment Act of 2009.

Visit Project Page

Lakewood, CO 80215

Government

6700

Installer

Visit Project Page

Lakewood, CO 80215

Government

6700

Installer

Phase I of this design-build project included the installation of 14,612 roof-mounted solar panels on Buildings 20, 56 and 810 at the Denver Federal Center campus. These three roof-top arrays are tied to the existing electrical distribution system. The system is 3.2 MW DC. This project was funded by the American Recovery and Reinvestment Act of 2009.

Visit Project Page

14000 E Exposition Ave, Aurora, CO 80012

Commercial Real Estate

280

Installer

Visit Project Page

14000 E Exposition Ave, Aurora, CO 80012

Commercial Real Estate

280

Installer

Visit Project Page

6675 Business Center Dr, Highlands Ranch, CO 80130

Commercial Real Estate

280

Installer

Visit Project Page

6675 Business Center Dr, Highlands Ranch, CO 80130

Commercial Real Estate

280

Installer

Visit Project Page

9499 Sheridan Boulevard, Westminster, CO 80031

Commercial Real Estate

280

Installer

Visit Project Page

9499 Sheridan Boulevard, Westminster, CO 80031

Commercial Real Estate

280

Installer

Visit Project Page

Denver, CO

Government

120

Installer

Visit Project Page

Denver, CO

Government

120

Installer

Installation of a 115.5 kW DC solar photovoltaic system on top of a new 7-level parking garage.

Visit Project Page

8000 E County Rd 106 N, Mosca, CO 81146, USA

Utility

30000

Installer

Visit Project Page

8000 E County Rd 106 N, Mosca, CO 81146, USA

Utility

30000

Installer

Visit Project Page

Henderson, NV

Commercial Real Estate

590

Installer

Visit Project Page

Henderson, NV

Commercial Real Estate

590

Installer

The 600 kW DC Cactus Garden Solar project consists of 2,112 photovoltaic modules on a 4-acre site and is the largest solar installation by a food manufacturer in Nevada. The Cactus Garden project generates renewable energy for the Ethel M® chocolate facility owned by the Mars Corporation. (Photos courtesy of juwi solar, inc.)

Visit Project Page

CO-115, Colorado Springs, CO 80913, USA

Government

300

Installer

Visit Project Page

CO-115, Colorado Springs, CO 80913, USA

Government

300

Installer

This 300 kW DC, design-build solar project was built at the Fort Carson Army Base. The array is located on several carport structures in the parking lot of a new Military Intelligence Battalion Headquarters building.

Visit Project Page

Chula Vista, CA

Industrial

2000

Installer

Visit Project Page

Chula Vista, CA

Industrial

2000

Installer

2MW distributed generation solar project behind the meter.

Visit Project Page

Ridgecrest, CA

Utility

11000

Installer

Visit Project Page

Ridgecrest, CA

Utility

11000

Installer

This solar project is expected to generate the equivalent of more than 30% of the Navy Air Weapons Station, China Lake’s annual energy load. This will help to reduce costs by an estimated $13 million over the next 20 years. Responsibilities included: civil, metal erection, module installation, A/C, D/C, substation tie-in and management services.

Visit Project Page

Alamosa, CO

Utility

30500

Installer

Visit Project Page

Alamosa, CO

Utility

30500

Installer

Visit Project Page

Fort Collins, CO

Education

120

Installer

Visit Project Page

Fort Collins, CO

Education

120

Installer

Visit Project Page

Mesa, AZ

Government

1000

Installer

Visit Project Page

Mesa, AZ

Government

1000

Installer

Visit Project Page

Modesto, CA

Utility

Installer

Visit Project Page

Modesto, CA

Utility

Installer

Located on 160 acres in eastern Modesto, California, this photovoltaic system will power the equivalent of over six thousand homes with renewable energy. E Light Wind and Solar, Inc. completed the electrical, AC, DC, and panel installation for this project.

Visit Project Page

Mosca, CO

Commercial Real Estate

Installer

Visit Project Page

Mosca, CO

Commercial Real Estate

Installer

Visit Project Page

Colorado Springs, CO

Commercial Real Estate

500

Installer

Visit Project Page

Colorado Springs, CO

Commercial Real Estate

500

Installer

Visit Project Page

Brighton, CO

Commercial Real Estate

2000

Installer

Visit Project Page

Brighton, CO

Commercial Real Estate

2000

Installer

Visit Project Page

Jacksonville, NC

Government

1000

Installer

Visit Project Page

Jacksonville, NC

Government

1000

Installer

This project is located on a 72,000 sf, raised seamed roof above a parking garage on the Camp Lejeune Marine Base. Onsite services included: racking installation, D/C, setting AC & DC equipment, module installation, DC array wiring, and DAS & MET Station monitoring and controls. Designed to withstand wind and seismic loads on the existing metal roof, using pre-engineered attachment methods.

Visit Project Page

Maiden, NC

Commercial Real Estate

24950

Installer

Visit Project Page

Maiden, NC

Commercial Real Estate

24950

Installer

This project is the nation’s largest on-site solar installation at an end user-owned facility. The 171 acre site includes a ground-mount, single axis tacker installation. The solar photovoltaic system supplies power to a $1 billion dollar existing data center on the site. The scope of work included installation of driven and drilled piers, erection of the single-axis tracking system, PV module installation, SCADA, and all DC and AC electrical work.

Visit Project Page

52500 West Baseline Road, Tonopah, AZ 85354

Utility

15000

Installer

Visit Project Page

52500 West Baseline Road, Tonopah, AZ 85354

Utility

15000

Installer

This 160-acre project, located near Phoenix, included the installation of 61,920 panels on a ground-mount of an ATI tracker system. E Light’s scope of work included module installation, A/C, D/C, and converter tie-in.

Visit Project Page

Breckenridge, CO

Commercial Real Estate

500

Installer

Visit Project Page

Breckenridge, CO

Commercial Real Estate

500

Installer

This is a 497KW ground mount solar project, which was built on an old gravel pit in Summit County, CO. BioStar and E Light’s responsibilities included module installation and converter tie-in.

Visit Project Page

7581 E Academy Blvd, Denver, CO 80230

Commercial Real Estate

400

Installer

Visit Project Page

7581 E Academy Blvd, Denver, CO 80230

Commercial Real Estate

400

Installer

Visit Project Page

Conover, NC

Commercial Real Estate

20000

Installer

Visit Project Page

Conover, NC

Commercial Real Estate

20000

Installer

The NC PV II Solar project is a 20MWac capacity and 25.05MWdc single-axis ground-mounted Solar Facility connected to Duke Energy. The project is located in Conover, NC, and covers approximately 115 acres. BioStar and E Light provided CM services, DC and MV electrical services, equipment signage, SCADA install, and commissioning of the facility.

Visit Project Page

29 Palms, CA

Commercial Real Estate

Installer

Visit Project Page

29 Palms, CA

Commercial Real Estate

Installer

Visit Project Page

Bakersfield, CA

Utility

26,000

Installer

Visit Project Page

Bakersfield, CA

Utility

26,000

Installer

This, 26 MW DC, the ground-mount solar project sits on approximately 160 acres outside of Bakersfield, CA. This project utilizes nearly 80,000 – 325 watt modules. E Light completed the electrical portion of this project and BioStar was the installer.

Visit Project Page

7165-7175 E Skyline Dr, Tucson, AZ 85718

Commercial Real Estate

Material Provider

Visit Project Page

7165-7175 E Skyline Dr, Tucson, AZ 85718

Commercial Real Estate

Material Provider

Visit Project Page

1201 Ferris Ave, Waxahachie, TX 75165

Commercial Real Estate

860

Installer

Visit Project Page

1201 Ferris Ave, Waxahachie, TX 75165

Commercial Real Estate

860

Installer

Visit Project Page

189 Sierra Way, Yerington, NV 89447

Utility

20000

Installer

Visit Project Page

189 Sierra Way, Yerington, NV 89447

Utility

20000

Installer

Fort Churchill is a very unique project in Yerington, NV approximately 50 miles southeast of Reno. This project uses mirrors to concentrate the sun’s power to a receiver which harnesses the energy.

Visit Project Page

1215 S State St, Dover, DE 19901

Commercial Real Estate

3500

Installer

Visit Project Page

1215 S State St, Dover, DE 19901

Commercial Real Estate

3500

Installer

Visit Project Page

31407-30001 McCabe Rd, Gustine, CA 95322

Utility

105000

Installer

Visit Project Page

31407-30001 McCabe Rd, Gustine, CA 95322

Utility

105000

Installer

Launch Development’s project revamped the old Gateway 2000 retail shopping center in Overland Park, KS. In addition to renovating the retail storefront and commercial parking lot, BioStar Renewables provided exterior site lighting for 420 new apartment units.

Visit Project Page

13001 E. Panama Lane, Bakersfield, CA 93307

Utility

65200

Installer

Visit Project Page

13001 E. Panama Lane, Bakersfield, CA 93307

Utility

65200

Installer

Visit Project Page

11414 W 79th St, Overland Park, KS 66214

Automotive

Developer

Visit Project Page

11414 W 79th St, Overland Park, KS 66214

Automotive

Developer

The large room with high ceilings at Aeromotive’s new facility required high lumen lights with excellent coverage. The factory LED lighting allows technicians to work with precision without straining to see the fuel system products??_they are building, while saving energy.

Visit Project Page

16611-16703 East 23rd St S, Independence, MO 64055

Commercial Real Estate

Developer

Visit Project Page

16611-16703 East 23rd St S, Independence, MO 64055

Commercial Real Estate

Developer

Visit Project Page

330 Greene St, Buffalo, NY 14206

Commercial Real Estate

Developer

Visit Project Page

330 Greene St, Buffalo, NY 14206

Commercial Real Estate

Developer

Visit Project Page

1600 NW Prairie View Rd, Platte City, MO 64079

Automotive

Developer

Visit Project Page

1600 NW Prairie View Rd, Platte City, MO 64079

Automotive

Developer

The car lot, service bays and parts department at Roberts automotive dealership had poor light coverage with multiple dark spots. BioStar designed a solution that increased light levels and saved energy, even after the addition of several exterior area lights. Lighting costs in the upgraded areas were reduced by 60% due to the combined energy and maintenance savings.

For the showcase lots, BioStar selected LED area lights designed for automotive dealership front lines and exterior retail applications. These industry-leading lights feature technology that showcases inventory in vivid, color-balanced light.

In the service bays, simply upgrading existing lights to LED lights achieved the optimal light quality that allows technicians to work with precision without straining their eyes.

Visit Project Page

13811 N Tatum Blvd, Phoenix, AZ 85032

Commercial Real Estate

Developer

Visit Project Page

13811 N Tatum Blvd, Phoenix, AZ 85032

Commercial Real Estate

Developer

Visit Project Page

7503 E 22nd St, Tucson, AZ 85710

Automotive

Material Provider - New Construction

Visit Project Page

7503 E 22nd St, Tucson, AZ 85710

Automotive

Material Provider - New Construction

Visit Project Page

2300 N 113th Terrace, Kansas City, KS 66109

Healthcare

Material Provider - New Construction

Visit Project Page

2300 N 113th Terrace, Kansas City, KS 66109

Healthcare

Material Provider - New Construction

The Piper is a unique luxury assisted living facility that utilizes an innovative design philosophy which provides a ???home within a home???. The??_design team??_transforms assisted living into warm, nurturing homes that foster independence. The lighting design helps create this atmosphere and contributes to residents’ health and well-being.??_LED lighting was an essential part of the new construction plans.??_BioStar provided over 3000 lights for the 100,000 square foot, 120 unit building complex and for the 5 acres of landscaping and parking.

Research has shown that LED lighting has positive effects on health including reducing headaches, nausea, Alzheimer’s disease and related dementias, mood disorders, stress, vision loss and eye disorders.

Visit Project Page

19498 Kent Ave, Lemoore, CA 93245

Utility

102000

Installer

Visit Project Page

19498 Kent Ave, Lemoore, CA 93245

Utility

102000

Installer

Located in Lemoore, CA Henrietta solar farm is a 127.50 MW solar power plant. Scope included all electrical work and module installation. This project contains a new version of Oasis 3 Tracking System with improvements to the DC cable tray and larger 2 MW blocks.

Visit Project Page

6000 Ikea Way, Merriam, KS

Commercial Real Estate

580

Installer

Visit Project Page

6000 Ikea Way, Merriam, KS

Commercial Real Estate

580

Installer

Visit Project Page

Claremont, NC

Commercial Real Estate

20000

Installer

Visit Project Page

Claremont, NC

Commercial Real Estate

20000

Installer

Claremont is a 21.92 MW project located in Claremont, NC. The project included a difficult off-site overhead medium voltage line to the substation at 35 KV.

Visit Project Page

Florence, AZ

Utility

50000

Installer

Visit Project Page

Florence, AZ

Utility

50000

Installer

The Boonybrooke Solar Farm is located in Florence, AZ and covers approximately 282 acres. The project is 50MWac capacity and 62.64MWdc, the power plant is connected to SRP energy. Provided CM services, PV installation, DC and MV electrical services, Equipment Signage, SCADA Install, and Commissioning of the facility. The Solar Plant is a single axis ground-mounted Utility-scale solar project with approximately 144,000 solar panels.

Visit Project Page

4579 Haynes Road, Elm City, NC

Utility

41600

Installer

Visit Project Page

4579 Haynes Road, Elm City, NC

Utility

41600

Installer

Elm City is a 53.62 MW solar power plant located in North Carolina. This project utilizes First Solar’s thin-film module technology mounted on a fixed-tilt racking system. It has a challenging 4-month construction schedule. E Light’s scope of work will include all electrical work and module installation.

Visit Project Page

Desert Center, CA 92239

Utility

260

Installer

Visit Project Page

Desert Center, CA 92239

Utility

260

Installer

This multi-phase, 260 megawatt, thin-film, fixed position, solar project is located in Desert Center, California. E Light performed the electrical scope of work on this project. Desert Sunlight Solar Farm provides enough energy to serve the needs of about 160,000 average California homes.

Visit Project Page

8720 E 63rd St, Kansas City, MO 64133

Commercial Real Estate

Developer

Visit Project Page

8720 E 63rd St, Kansas City, MO 64133

Commercial Real Estate

Developer

Planet Fitness is dedicated to providing the healthiest and most enjoyable environment for their customers. To meet this goal they realized they needed to increase light levels in their facility. LED lights have been shown to improve people’s physical and mental well-being, increasing energy levels because of their similarity to natural sunlight. BioStar was able to provide a cost-effective way to brighten the environment in the gym. Lighting costs were cut in half so the fitness center LED lighting upgrade will pay for itself.

Visit Project Page

Kansas City, MO

Industrial

Developer

Visit Project Page

Kansas City, MO

Industrial

Developer

BioStar provided new office and warehouse lighting for Haith & Co. on a tenant improvement project for their tenant, Air General. BioStar replaced 130 warehouse and office fixtures with 114 LED fixtures, which will save more than $60,000 in energy savings over the next 10 years while eliminating lighting maintenance for their tenant.

Visit Project Page

1290 Arrowhead Ct, Crown Point, IN 46307

Commercial Real Estate

2

Developer

Visit Project Page

1290 Arrowhead Ct, Crown Point, IN 46307

Commercial Real Estate

2

Developer

Visit Project Page

880 S Pleasantburg Dr Building 4 Suite C, Greenville, SC 29607

Commercial Real Estate

9

Developer

Visit Project Page

880 S Pleasantburg Dr Building 4 Suite C, Greenville, SC 29607

Commercial Real Estate

9

Developer

Visit Project Page

10841 State Line Rd, Kansas City, MO 64114

Multifamily

Developer

Visit Project Page

10841 State Line Rd, Kansas City, MO 64114

Multifamily

Developer

BioStar Renewables has partnered with Eighteen Capital Group on several turnkey LED lighting projects across their portfolio of multifamily properties. BioStar’s team enjoyed brightening up this South Kansas City community near I-435 & State Line Road.

Visit Project Page

5901 E 81st Ave, Merrillville, IN 46410

Commercial Real Estate

Developer

Visit Project Page

5901 E 81st Ave, Merrillville, IN 46410

Commercial Real Estate

Developer

Visit Project Page

7500 Grade Ln, Louisville, KY 40219

Commercial Real Estate

Developer

Visit Project Page

7500 Grade Ln, Louisville, KY 40219

Commercial Real Estate

Developer

BioStar Renewables provided a turnkey LED lighting retrofit for Central Farm Supply in Kentucky. Substantial energy savings and a dramatic improvement in quality of light made this project a success.

Visit Project Page

6801 Holmes Rd, Kansas City, MO 64131

Education

2

Developer

Visit Project Page

6801 Holmes Rd, Kansas City, MO 64131

Education

2

Developer

Visit Project Page

4020 Meeting Way, High Point, NC 27265

Education

Developer

Visit Project Page

4020 Meeting Way, High Point, NC 27265

Education

Developer

Visit Project Page

11500 N Ambassador Dr #360, Kansas City, MO 64153

Commercial

2

Developer

Visit Project Page

11500 N Ambassador Dr #360, Kansas City, MO 64153

Commercial

2

Developer

Visit Project Page

144 Jetplex Ln, Madison, AL 35758

Commercial Real Estate

Developer

Visit Project Page

144 Jetplex Ln, Madison, AL 35758

Commercial Real Estate

Developer

Visit Project Page

77 Seascape Dr, Destin, FL 32550

Multifamily

Developer

Visit Project Page

77 Seascape Dr, Destin, FL 32550

Multifamily

Developer

Visit Project Page

Google City, CA

Commercial Real Estate

Developer

Visit Project Page

Google City, CA

Commercial Real Estate

Developer

BioStar installed 223 LED high bay fixtures as a part of a tenant improvement project for SF Spice’s new facility in California.

Visit Project Page

507 Bell Fork Rd, Jacksonville, NC 28540

Commercial Real Estate

Developer

Visit Project Page

507 Bell Fork Rd, Jacksonville, NC 28540

Commercial Real Estate

Developer

Visit Project Page

400 W 49th Terrace, Kansas City, MO 64112

Multifamily

Developer

Visit Project Page

400 W 49th Terrace, Kansas City, MO 64112

Multifamily

Developer

The Alameda Towers Condos LED lighting upgrade greatly improved the color and coverage of light in the garage, while at the same time reducing the building’s lighting bill by nearly 165,000 kWh annually, for a payback period of 1.4 years.

The new CREE VG Series fixtures include dimming sensor controls that give the customer the ability to select which lights use a motion sensor to brighten when needed and which lights are on bright continually.

Visit Project Page

10920 Nall Aveneu, Overland Park, KS 66211

Hospitality

Developer

Visit Project Page

10920 Nall Aveneu, Overland Park, KS 66211

Hospitality

Developer

Being a busy hotel, a flexible installation schedule was very important to Holiday Inn. ??_BioStar worked with the manager??_to coordinate a plan for retrofitting the entire hotel.??_ The upgrades were completed in stages to ensure that it did not interfere with guests’ experience or bookings.

The energy efficient lighting and reduced waste from replacement bulbs also aligns with the InterContinental Hotel Group’s Green Engage sustainability initiative. The new hotel LED lighting uses 62% less energy, and maintenance costs are eliminated during their 10-year average lifetime resulting in a 75% reduction in lighting costs.

Visit Project Page

13201 Arrington Rd, Grandview, MO 64030, USA

Industrial

Developer

Visit Project Page

13201 Arrington Rd, Grandview, MO 64030, USA

Industrial

Developer

U.S. Toy improved the quality of light in their office while achieving a 64% energy savings. Their project earned them an award from the Department of Energy’s Better Buildings Challenge Interior Lighting Campaign.

BioStar upgraded over 450 LED lights in a weekend without disrupting business. Employees were amazed to see the difference in light color and quality when they returned! BioStar Lighting’s flexible installation schedule combined with the fast and clean 1-minute installation of Orion Energy Systems LDR Troffer Retrofit lights make lighting upgrades easy for any business.

Pleased with the retrofit of their offices, US Toy continued the lighting upgrades in their warehouse. By choosing a variety of warehouse LED lighting fixtures to meet their needs, the building now uses nearly 70% less energy, with an annual savings of 256,000 KWH, and an investment payback of less than 2 years.

The energy savings as well as the improvement in lighting color and brightness are remarkable when upgrading metal halide or high pressure sodium lamps. In the before photo, the contrast is significant between the daylight entering the building and the metal halide lamps. After the installation, the warehouse LED lights match the lighting color temperature of natural light.

Visit Project Page

Troost Ave &, E Meyer Blvd, Kansas City, MO 64131

Commercial Real Estate

Developer

Visit Project Page

Troost Ave &, E Meyer Blvd, Kansas City, MO 64131

Commercial Real Estate

Developer

Block & Co. began upgrading the lighting in their portfolio of commercial properties with the complete retrofit of the Landing Mall. BioStar replaced over 300 fixtures and over 1,500 lamps in the center court, hallways, parking lots and Tres Bliss store with energy efficient LEDs. Timers and dual switching add control and energy savings.

Updating to commercial LED lighting gave the mall a stylish modern look and improved the customer experience. Security staff appreciates the brighter light and better coverage in the parking lots, and building managers enjoy the 71% reduction in lighting costs that save them nearly $1 million over 10 years. The project was completed with Landing Venture Associates, managed by Block & Co realtors.

Visit Project Page

13715 W 151st St, Olathe, KS 66062

Commercial Real Estate

2

Developer

Visit Project Page

13715 W 151st St, Olathe, KS 66062

Commercial Real Estate

2

Developer

When Grace Church began the expansion of their building, they knew they wanted their new facilities to have a modern and welcoming ambience. Recognizing that high-quality LED lighting design would help fulfill this goal, they employed BioStar’s team in designing lighting solutions tailored to each space. The result is an elegantly modern church that guests delight in visiting. In addition to a modern look and feel, Grace Church also wanted an energy efficiency solution that would both benefit the environment and reward them with financial savings. They discovered that LED lighting would significantly reduce energy use with a relatively small increase in their construction costs. The church will save approximately $476,000 on outdoor lighting costs alone.

Visit Project Page

Commercial Real Estate

3

Developer

Visit Project Page

Commercial Real Estate

3

Developer

Visit Project Page

605 W. 47th Street, Kansas City, MO 64112

Commercial Real Estate

2

Developer

Visit Project Page

605 W. 47th Street, Kansas City, MO 64112

Commercial Real Estate

2

Developer

BioStar Renewables worked with Block & Co. to upgrade the LED lighting throughout all common areas, offices and the parking garage in this iconic Plaza building. Block & Co. has been aggressive in achieving sustainability and energy related goals across their portfolio, working on several projects with the BioStar team to improve their tenant’s space while saving energy and money.

A leader in commercial real estate service and innovation, Block & Company Inc. has established an initiative to save energy and money across their portfolio of properties. Searching for energy efficiency solutions that make economic sense, they partnered with BioStar and completed LED projects at the Skelly Building, The Landing Mall, Summit Woods pads and Summit Crossing.

At the Skelly Building on the Country Club Plaza, home of Block & Company Inc.’s headquarters, the LED upgrade of more than 1100 fixtures achieved 71% energy reduction, saving almost 300,000 kilowatt-hours per year. Including maintenance savings, the retrofit reduces total lighting costs by 75%, resulting in a 1.9-year payback after a rebate from KCP&L.

Visit Project Page

139 Southwest Dr, Jonesboro, AR 72401

Industrial

43

Developer

Visit Project Page

139 Southwest Dr, Jonesboro, AR 72401

Industrial

43

Developer

Visit Project Page

114 W 11th St #200, Kansas City, MO 64105

Commercial Real Estate

10

Developer

Visit Project Page

114 W 11th St #200, Kansas City, MO 64105

Commercial Real Estate

10

Developer

MC Realty is a leader in commercial building efficiency, especially in downtown Kansas City. MC Realty has done more than just promote energy efficiency, they have implemented energy efficiency aggressively in their buildings. BioStar and MC Realty have partnered on nine LED lighting projects, mainly retrofitting parking garages and stairwells. Notable projects include the garage at the Marriott Downtown and the Broadway Square Building.

The projects received two awards from the Department of Energy and US Green Building Council’s 2016 LEEP campaign for Highest Percentage Energy Savings in a Retrofit at a Single Parking Structure and Exemplary Office Sector Parking Facility.

In total, the projects will save an estimated 2,000,000 kWh per year. This will reduce lighting costs for electricity and maintenance by more than 80%, saving more than $265,000 annually with a payback of three years. The brighter light and better coverage improves safety and security for the tenants and visitors.

Visit Project Page

4301 Forest St, Denver, CO 80216, USA

Industrial

Rebates

Visit Project Page

4301 Forest St, Denver, CO 80216, USA

Industrial

Rebates

Visit Project Page

2035 2nd Ave, Greeley, CO 80631, USA

Industrial

Rebates

Visit Project Page

2035 2nd Ave, Greeley, CO 80631, USA

Industrial

Rebates

Visit Project Page

Mayfield, KY

Commercial Real Estate

Developer

Visit Project Page

Mayfield, KY

Commercial Real Estate

Developer

BACK TO PORTFOLIO

Visit Project Page

5199 Ivy St, Commerce City, CO 80022, USA

Industrial

Rebates

Visit Project Page

5199 Ivy St, Commerce City, CO 80022, USA

Industrial

Rebates

Visit Project Page

4221 Monaco St, Denver, CO 80216, USA

Industrial

Rebates

Visit Project Page

4221 Monaco St, Denver, CO 80216, USA

Industrial

Rebates

Visit Project Page

1530 E 64th Ave, Denver, CO 80229, USA

Industrial

Rebates

Visit Project Page

1530 E 64th Ave, Denver, CO 80229, USA

Industrial

Rebates

Visit Project Page

11955 E Peakview Ave, Englewood, CO 80111, USA

Industrial

Rebates

Visit Project Page

11955 E Peakview Ave, Englewood, CO 80111, USA

Industrial

Rebates

Visit Project Page

2522 W. 21st Street, Chanute, KS 66720

Industrial

Material Provider - New Construction

Visit Project Page

2522 W. 21st Street, Chanute, KS 66720

Industrial

Material Provider - New Construction

Visit Project Page

500 Industrial Rd A, Grove, OK 74344

Industrial

Material Provider

Visit Project Page

500 Industrial Rd A, Grove, OK 74344

Industrial

Material Provider

Visit Project Page

7899 Wadsworth Blvd, Arvada, CO 80003

Commercial Real Estate

2900

Installer

Visit Project Page

7899 Wadsworth Blvd, Arvada, CO 80003

Commercial Real Estate

2900

Installer

Rooftop-mounted Photovoltaic systems totaling 1.85MWdc on four Colorado Target Stores. The stores are located in Arvada, Aurora, Edgewater and Englewood Colorado. These SunPower projects are part of Target’s initiative to put solar on 200 of their stores.

Visit Project Page

Cochise, AZ

Utility

20000

Installer

Visit Project Page

Cochise, AZ

Utility

20000

Installer

The Sulphur Springs Solar project is a 22.97 MW solar photovoltaic generation facility located in Cochise, AZ. The projects site is approximately 130 acres. Three of the nine blocks that complete the facility utilize a new proprietary voltage limiting device. It allows a 25% increase in modules per string, reducing the number of DC strings per MW of Solar.

Visit Project Page

Bennett, CO

Utility

12830

Installer

Visit Project Page

Bennett, CO

Utility

12830

Installer

The Victory Solar Project is a 15.90 MW project just north of Bennet, CO in Adams County. This project is situated on 160 acres. Notable structures on the site include a substation, an airport beacon, and overhead power lines. E Light installed the PV Modules in addition to the electrical work on this project.

Visit Project Page

1325 W 8900 N St, Fillmore, UT 84631

Utility

20000

Installer

Visit Project Page

1325 W 8900 N St, Fillmore, UT 84631

Utility

20000

Installer

E Light was responsible for all AC, DC, grounding, control wiring, module installation and wire management on this 25.37 MW tracker project. We also performed the lay out and conduit installation of 11 PCS inverter pads along with setting and connecting all equipment. This project utilized an above ground cable tray system for routing DC and control cabling that connected through an in ground concrete vault to the equipment pad. The medium voltage cables, however were all underground.

Visit Project Page

Windsor, CO

Utility

30000

Installer

Visit Project Page

Windsor, CO

Utility

30000

Installer

Bison Solar is a 36.31 MW photovoltaic electricity-generated facility located adjacent to the Rawhide Energy Plant, spanning nearly 250 acres north of Wellington, Colorado. BioStar installed PV modules and the electrical.

Visit Project Page

Lamesa, TX

Utility

100

Installer

Visit Project Page

Lamesa, TX

Utility

100

Installer

The Lamesa Solar Project is 100MWac capacity and 130.5MWdc single-axis ground mounted Solar Facility. The project is located in Lamesa, TX and covers approximately 887 acres in Dawson County. The project includes over 410,000 polycrystalline solar panels with BioStar’s oversight of CM services, DC and MV electrical services, equipment signage, SCADA install, and commissioning of the facility.

Visit Project Page

5414 E. Front Street, Kansas City, MO 64120

Commercial Real Estate

Developer

Visit Project Page

5414 E. Front Street, Kansas City, MO 64120

Commercial Real Estate

Developer

When the property manager at Cargo Largo learned of the benefits of LED lighting, he decided that replacing their energy efficient fluorescent lighting would resolve several issues. The motivation to upgrade came from not only the energy savings, but also the improved light in the warehouses full of inventory, the ability to resolve lighting design issues, and the elimination of bulb replacement.

BioStar retrofitted 800,000+ square feet including three warehouses, offices and exterior flood lights. The lighting design was improved by moving fixtures that were above shelving to the ideal location in the center of aisles. Occupancy sensors increase energy savings and simplify the workflow in the warehouses. Even with the extra costs of moving lights, adding sensors, and replacing energy efficient fluorescents, Cargo Largo will save over $200,000 after project costs over 10 years.

Visit Project Page

North Kansas City, MO

Commercial Real Estate

Developer

Visit Project Page

North Kansas City, MO

Commercial Real Estate

Developer

Visit Project Page

Lee's Summit, MO

Commercial Real Estate

Developer

Visit Project Page

Lee's Summit, MO

Commercial Real Estate

Developer

BioStar Renewables worked with Block and Co. to upgrade the LED lighting on the exterior of this retail shopping center in Lee’s Summit, MO. This project is providing energy savings and operational cost savings related to lighting maintenance, but perhaps most importantly, it is providing a safer environment for patrons of the shops.

Visit Project Page

235 Ward Pkwy, Kansas City, MO 64112

Multifamily

Developer

Visit Project Page

235 Ward Pkwy, Kansas City, MO 64112

Multifamily

Developer

Locarno Plaza offers contemporary luxury living, so top-quality LED lighting that matches the old world charm makes sense both economically and aesthetically. BioStar upgraded the lighting in the common areas including the lobby, hallways, parking garage, elevators, offices, as well as exterior landscape and security lighting. Between energy savings and replacement bulbs, the project will save an estimated 180,000 kWh annually, resulting in a project payback of 1.8 years! Additionally, the time saved allows maintenance to focus on other upgrades and repairs.

Visit Project Page

904 E 68th St, Kansas City, MO 64131

Healthcare

Developer

Visit Project Page

904 E 68th St, Kansas City, MO 64131

Healthcare

Developer

In 2015, Tutera Group began retrofitting fluorescent and metal halide fixtures throughout their senior living and commercial real estate portfolio. Highland benefitted from an interior and exterior commercial LED lighting upgrade consisting of more than 300 fixtures. The turnkey installation resulted in a zero-maintenance solution and more than 210,000 kWh saved annually.

Visit Project Page

8901 South Blvd, Charlotte, NC 28273

Automotive

Developer

Visit Project Page

8901 South Blvd, Charlotte, NC 28273

Automotive

Developer

BioStar Renewables was selected to upgrade the exterior and shop lighting at this premier dealership in Charlotte. BioStar has been proud to partner with Hendrick Automotive on several subsequent projects as they continue to address energy efficiency and wuality of light across their dealerships.

Visit Project Page

237 22nd St, Greeley, CO 80631

Commercial Real Estate

Developer

Visit Project Page

237 22nd St, Greeley, CO 80631

Commercial Real Estate

Developer

Visit Project Page

3712 E 47th Terrace, Kansas City, MO 64130

Healthcare

Developer

Visit Project Page

3712 E 47th Terrace, Kansas City, MO 64130

Healthcare

Developer

In 2015, Tutera Group began retrofitting fluorescent and metal halide fixtures throughout their senior living and commercial real estate portfolio. Plaza Manor benefitted from an interior and exterior commercial LED lighting upgrade, consisting of 400 fixtures. The turnkey installation resulted in a zero-maintenance solution and more than 110,000 kWh saved annually.

Visit Project Page

Chanute, KS

Industrial

Developer

Visit Project Page

Chanute, KS

Industrial

Developer

BioStar’s LED lighting design team helped design and procure lighting for this new construction project in Chanute, KS. Tech Industries, now called Orizon Aerostructures, provides complex subassemblies for the aerospace industry.

Visit Project Page

9001 State Line Road, Kansas City, MO 64114

Commercial Real Estate

Developer

Visit Project Page

9001 State Line Road, Kansas City, MO 64114

Commercial Real Estate

Developer

BioStar Renewables has partnered with The Tutera Group’s commercial real estate team to upgrade this building as a part of a large renovation of the asset. BioStar helped bring the design team’s vision to life with bright, long-lasting, energy efficient lighting. BioStar provided design and photometric support, as well as supplied the entire fixture package for the remodel.

Visit Project Page

7611 State Line Rd, Kansas City, MO 64114

Commercial Real Estate

Developer

Visit Project Page

7611 State Line Rd, Kansas City, MO 64114

Commercial Real Estate

Developer

In addition to upgrading their portfolio of senior living communities and commercial real estate properties, Tutera Group retrofitted their Kansas City headquarters with advanced LED lighting. The project received an award in exemplary commercial real estate and the hospitality sector from the Department of Energy’s Better Buildings Challenge Interior Lighting Campaign. The award recognized outstanding performance in BioStar’s application of high efficiency troffer lighting systems and Tutera Group’s commitment to energy reduction. More than 600 lights were retrofitted, reducing the building’s lighting energy use by 62% and saving over 100,000 kWh of electricity per year.

Visit Project Page

107 Bernard Drive, Belton, MO 64012

Healthcare

Developer

Visit Project Page

107 Bernard Drive, Belton, MO 64012

Healthcare

Developer

Tutera Group, a commercial real estate and senior living management company updated 13 of their properties with turnkey LED retrofits.

BioStar was selected to perform the lighting design and fixture procurement for The Tutera Group’s Memory Care expansion at their Carnegie Village Senior Living Community and to help bring their vision for this amazing facility to life. BioStar had previously retrofitted the existing facility to energy efficient LED decorative and commercial fixtures and were hired a second time to upgrade more than 800 lights which resulted in estimated energy savings of 335,000 kilowatt-hours, with a two year payback.

Research has shown that LED lighting has positive effects on health including reduction in age-related disorders, headaches and vision loss, making LEDs ideal for senior living communities.

Visit Project Page

400 W 4th St, Lockwood, MO 65682

Education

Developer

Visit Project Page

400 W 4th St, Lockwood, MO 65682

Education

Developer

BioStar Renewables worked with a partner, Navitas, to complete a district-wide LED lighting upgrade for Lockwood, including their largest facility, the high school. The students in the district will benefit from an enhanced learning environment, while the district benefits from operational savings.

Visit Project Page

310 Broadway Blvd., Kansas City, MO 64105

Commercial Real Estate

Developer

Visit Project Page

310 Broadway Blvd., Kansas City, MO 64105

Commercial Real Estate

Developer

BioStar Renewables has partnered with MC Realty Group to tackle a variety of projects in this landmark building in downtown Kansas City. A very busy building with significant foot traffic for extended hours, lighting is of utmost importance, which is why BioStar and MC Realty teamed up to retrofit comon area downlights, reccessed tracks and troffers with long-lasting, energy efficient LEDs that will pay for themselves ten times over.

Visit Project Page

4615 S Virginia St, Amarillo, TX 79109

Multifamily

Developer

Visit Project Page

4615 S Virginia St, Amarillo, TX 79109

Multifamily

Developer

BioStar Renewables worked with Eighteen Capital Group to upgrade the lighting at this apartment community in Texas. Improving the light levels around the community, as well as achieving operational savings were the main goals, both of which were achieved in this successful project. BioStar provides on-going warranty support to Eighteen Capital Group across a variety of projects in which BioStar has previously provided turnkey services.

Visit Project Page

7975 N Hayden Rd, Scottsdale, AZ 85258, USA

Education

Developer

Visit Project Page

7975 N Hayden Rd, Scottsdale, AZ 85258, USA

Education

Developer

BioStar has supplied energy efficient lighting to all 16 of Basis’ new school builds from California to New York since 2012. At first, the architect on the jobs specified traditional lighting. Eventually, he saw that on average, each school is able to save about $25,000/year from reduced energy consumption, and a further $7,000/year in maintenance savings through avoided bulb and ballast replacement. The LED lights use 60-65% less energy. Now the architect understands that energy efficient lighting in schools is a smart choice, and specs LED lights in all new builds. BioStar supplies the whole lighting package, right down to the exit signs.

Visit Project Page

1601 St Louis Ave, Kansas City, MO 64101

Multifamily

4

Developer

Visit Project Page

1601 St Louis Ave, Kansas City, MO 64101

Multifamily

4

Developer

BioStar worked with NFI Management to update their properties across the KC metro with energy efficient LED lighting. BioStar was able to capture significant rebate dollars from the Evergy energy efficiency rebate program, and achieve a fast project payback. The properties will benefit from significant energy and maintenacne savings, as well as improved security and safety for years to come.

Visit Project Page

Gladstone, MO

Multifamily

Developer

Visit Project Page

Gladstone, MO

Multifamily

Developer

BioStar Renewables implemented a community-wide LED lighting retrofit project to improve light levels around the exterior and common areas of this apartment community in Gladstone. Energy and maintenance savings, combined with a safer, brighter environment made this project a success.

Visit Project Page

401 NE Colbern Rd, Lee's Summit, MO 64086

Commercial Real Estate

Material Provider - New Construction

Visit Project Page

401 NE Colbern Rd, Lee's Summit, MO 64086

Commercial Real Estate

Material Provider - New Construction

Visit Project Page

1500 E 46th St, Kansas City, MO 64110

Multifamily

Developer

Visit Project Page

1500 E 46th St, Kansas City, MO 64110

Multifamily

Developer

BioStar Renewables upgraded a variety of exterior fixtures including wall packs, flood lights, and decorative lighting to improve the light levels across this vast apartment community in the heart of the KC metro.

Visit Project Page

408 N Locust St, Lockwood, MO 65682

Education

Developer

Visit Project Page

408 N Locust St, Lockwood, MO 65682

Education

Developer

BioStar Renewables worked in conjunction with our partner, Navitas, to complete a district-wide LED lighting upgrade for Lockwood School District. By retrofitting fluorescent fixtures with energy efficient LED lamps and fixtures, BioStar helped the school district achieve their energy savings goals and improve the learning environment district wide.

Visit Project Page

9101 N. Ambassador Drive, Kansas City, MO 64154

Commercial Real Estate

Material Provider - New Construction

Visit Project Page

9101 N. Ambassador Drive, Kansas City, MO 64154

Commercial Real Estate

Material Provider - New Construction

One of the premier senior living communities in the Kansas City area, Tiffany Springs provides luxury residences and first-in-class care for Kansas City’s seniors in the Northland. BioStar is extremely proud to have partnered on yet another fantastic project with the Tutera Group, a leading provider in Kansas City and across the country. BioStar provided lighting design services and procured all of the fixtures and lighting controls throughout the facility. It was a pleasure to help the Tutera Group design team execute their vision for this community.

Visit Project Page

801 Pennsylvania Avenue, Kansas City, MO 64105

Commercial Real Estate

Developer

Visit Project Page

801 Pennsylvania Avenue, Kansas City, MO 64105

Commercial Real Estate

Developer

An iconic part of the Northern skyline, the State Street building is now the home to the United States Department of Agriculture. BioStar Renewables partnered with MC Realty Group, a first-in-class, facility operations provider in Kansas City, to replace the old metal halide parking fixtures with energy efficient LEDs that reduced lighting operating costs more than 90%.

Visit Project Page

4945 Hadley St, Overland Park, KS 66203

Commercial Real Estate

Developer

Visit Project Page

4945 Hadley St, Overland Park, KS 66203

Commercial Real Estate

Developer

BioStar Renewables worked with Golden Boy to provide LED lighting upgrades in their store.

Visit Project Page

8961 Metcalf Ave, Overland Park, KS 66212

Multifamily

Material Provider - New Construction

Visit Project Page

8961 Metcalf Ave, Overland Park, KS 66212

Multifamily

Material Provider - New Construction

Launch Development’s project revamped the old Gateway 2000 retail shopping center in Overland Park, KS. In addition to renovating the retail storefront and commercial parking lot, BioStar Renewables provided exterior site lighting for 420 new apartment units.

Visit Project Page

4100 W. 85th Street, Prairie Village, KS 66026

Healthcare

Material Provider - New Construction

Visit Project Page

4100 W. 85th Street, Prairie Village, KS 66026

Healthcare

Material Provider - New Construction

Mission Chateau opened for business the Spring of 2018 in Prairie Village, Kansas. BioStar Renewables procured the lighting package for The Tutera Group’s newest, state-of-the-art assisted living community. The Tutera Group has been committed to sustainability, working with BioStar on 15+ LED lighting retrofit and new construction projects over the past three years. From custom chandeliers to back-of-the-house LED strips and troffers, Mission Chateau is 100% equipped with LED lighting, providing a bright, healthy community for seniors in Kansas City.

Visit Project Page

South Conejos Re-10, Antonito, CO 81120

Commercial Real Estate

1500

Installer

Visit Project Page

South Conejos Re-10, Antonito, CO 81120

Commercial Real Estate

1500

Installer

The Antonito II Solar Project is 1,200KWac capacity and 1,500kWdc Single Axis Tracker Solar Facility. The project is located near Antonito, CO and covers approximately 12 acres in Conejos County. The project will have 4,760 solar panels. Provided CM services, DC and MV electrical services, pile and racking installation, equipment signage, perimeter fence, civil work, SCADA install, and commissioning of the facility.

Visit Project Page

Old US Hwy 80, Gila Bend, AZ 85337

Commercial Real Estate

880

Installer

Visit Project Page

Old US Hwy 80, Gila Bend, AZ 85337

Commercial Real Estate

880

Installer

The APS Paloma Solar Project is a 886kWdc fixed tilt ground mounted Solar Facility. The project is located in Gila Bend, AZ and covers approximately 8 acres. This project is an addition to the original Paloma project and contains 8,440 thin film solar modules. Provided construction management services, DC and MV electrical, pile and racking installation, equipment signage, SCADA install, and commissioning of the facility.

Visit Project Page

200 W. 12th Street, Kansas City, MO 54105

Commercial Real Estate

Developer

Visit Project Page

200 W. 12th Street, Kansas City, MO 54105

Commercial Real Estate

Developer

BioStar Renewables was selected to replace the metal halide fixtures in the parking garage at this iconic hotel which has been a feature of the Kansas City skyline for decades. Using energy efficient LED fixtures and enhanced photometric design, the BioStar team was able to drastically improve the light levels in the garage, all while generating big savings for our customer. The fixtures utilize built-in infrared sensors to maximize savings by slightly dimming and conserving energy during times with no foot or vehicle traffic. BioStar has been partnered with several projects at the Kansas City Marriott Downtown related to energy efficiency and building optimization.

BioStar Renewables was proud to be invited back to the Marriott Downtown Kansas City to help tackle an interior lighting project primarily consisting of “”back of the house”” lighting, stairwells and more. Many of the fixtures replaced or retrofitted are operational 24/7, which created substantial energy savings and a fast payback. The hotel was able to further utilize Evergy’s energy efficiency rebate program to help pay for the project.

Visit Project Page

5630 Brystone Drive, Houston, TX 77041

Commercial Real Estate

Developer

Visit Project Page

5630 Brystone Drive, Houston, TX 77041

Commercial Real Estate

Developer

Curtis Wagner Plastics selected BioStar Renewables to retrofit and replace their lighting with energy efficient LED lamps and fixtures. As a manufacturing business, lighhting was important and the upgrade was well recevied from the production floor. Beyond better quality of light, C.W. Plastics will benefit from substantial energy savings and reduction in lighting maintenance.

Visit Project Page

2501 McGee Street, Kansas City, MO 64108

Commercial Real Estate

4

Developer

Visit Project Page

2501 McGee Street, Kansas City, MO 64108

Commercial Real Estate

4

Developer

Hallmark worked with BioStar to retrofit parking garages, starting with the very prominent Crown Center Parking garage. Hallmark wanted a new aesthetic that would reflect the design of the new Halls store. The resulting transformation has received extremely positive responses regarding the light output, aesthetics, and energy efficiency. Hallmark is so pleased with the new lights that they decided to retrofit other nearby parking garages.

Once again, Hallmark is leading the way in adopting cutting-edge technology, with extremely positive results. At the turn of the century, when many artists and photographers still insisted that art doesn’t belong on computers, Hallmark insisted on going digital. Now at a time when many people still worry about the quality of light and cost of LED lighting, Hallmark has seen the light and recognized the benefits of transitioning to LED lighting.

BioStar’s Custom Solution Delivers a Brilliant Aesthetic

BioStar designed a solution to meet their goal. The dimly lit garage was a stark contrast to the bright, cheerful shopping complex to which it is attached. Hallmark wanted a new aesthetic that would reflect the changes that were happening on the inside. Halls on Grand expanded and redesigned their store so it is bright and airy, sophisticated and modern, and at the same time, welcoming to all. The goal was to extend the changes to the outside, so that visitors’ entire experience, from the time they park to the time they leave, is brilliant.

The resulting transformation has received extremely positive responses regarding the light output, aesthetics, and energy efficiency. The old fluorescent lighting was unreliable, dimming as temperatures dropped. It did not provide good light coverage, with some areas being darker than others. And the color of the light was unappealing. LEDs deliver much more reliable, appealing light that travels farther, making the entire room brighter. The difference is clear as visitors enter the renovated third floor.

Plans for the Future Will Save Energy and Money“I am absolutely thrilled with the outcome of the Halls on Grand parking garage lighting project!” said Dana Clark, the Staff Engineering Consultant for Crown Center Redevelopment Corporation. “This is in large part due to the customer service provided by David and the entire BioStar Lighting team. From getting an amazing price on my fixture selection clear through the final installation and helping us re-order the handheld lighting control that was lost in the shuffle, David’s attention to the project details and timely communication was what customer service is all about. Thank you, BioStar!”

Hallmark is so pleased with the new lights that they are considering retrofitting more than 900 fixtures in nearby garages. In 2015, they replaced 440 high-pressure sodium lamps in a second garage with LED lights. BioStar’s projections estimated that the new lights will result in an estimated 76% energy reduction, saving Hallmark more than $766,000 over 10 years, and the payback period will be less than 2 years. Additionally, the project will result in 1,212,577 pounds of CO2 avoided. LED Industry Research Delivers Results

The industry has rapidly improved LED technology over the last few years, gaining control over lighting color & output, cost, and durability. Energy efficiency is not the only benefit. There are numerous advantages to converting to LED, many which are clearly seen at Crown Center.

Visit Project Page

815 E. 16th Street, Loveland, CO 80538

Commercial Real Estate

Developer

Visit Project Page

815 E. 16th Street, Loveland, CO 80538

Commercial Real Estate

Developer

BioStar Renewables helped Zion Lutheran Church upgrade their fluorescent and inadescent lighting to LED, improving the quality of light in the church while eliminating lighting maintenance and creating significant energy savings!

Visit Project Page

7595 Gadsden Hwy, Trussville, AL 35173

Commercial Real Estate

Developer

Visit Project Page

7595 Gadsden Hwy, Trussville, AL 35173

Commercial Real Estate

Developer

BioStar Renewables was selected to perform a site-wide LED lighting upgrade, which included enhanced lighting controls that would optimize the plant’s operations and savings. The graphic below shows the electricity usage of one of the buildings in the plant pre- and post-LED upgrade. Lighting controls help customers maximize savings and improve the life cycle of the LED fixtures that they control. Our customer will enjoy energy savings and operational savings, with a brighter plant for years to come, all with the comfort of extended product warranties in case of failures for 10-years.

Visit Project Page

237 22nd Street, Greeley, CO 80631

Commercial Real Estate

Developer

Visit Project Page

237 22nd Street, Greeley, CO 80631

Commercial Real Estate

Developer

Visit Project Page

9707 Tsuchiya Road, Waimea, HI 96796, USA

Education

251

Financier-Owner

Visit Project Page

9707 Tsuchiya Road, Waimea, HI 96796, USA

Education

251

Financier-Owner

Penetrating Roof Mounted, Fixed Tilt System

Visit Project Page

45985 Vía Tornado, Temecula, CA 92590, USA

Government

2260

Developer

Visit Project Page

45985 Vía Tornado, Temecula, CA 92590, USA

Government

2260

Developer

Situated on 16 acres approximately 4 miles southwest of Temecula, CA sits the Santa Margarita Ecological Reserve (SMER) Research 1 Solar project, which serves the City of Temecula and Lake Elsinore with clean, renewable energy. The 3.7 MWdc project, which is powered by more than 10,000 photovoltaic (PV) modules, will displace over 4.5 metric tons of carbon dioxide equivalent emissions per year, the equivalent of taking 971 cars off the road annually. The cities will purchase the clean energy generated by the solar farm to reduce the cost of power from the local utility company by approximately 15%.

In addition to the public benefits of lower electricity rates and obtaining electricity from a renewable source of power, SMER Research 1 and San Diego State University have agreed to conduct substantial academic research projects at the solar power generating facility site that will study solar radiation, solar energy, soils, and other meteorological and geotechnical data as well as habitat and habitat restoration after the contract ends.

BioStar provided the development, engineering, procurement, and construction (EPC) services, as well as ongoing operations and maintenance (O&M) and asset management services. California based contractor, Spectrum Energy Development Inc. played a pivotal role in site installation activities and services. The project created jobs for about 30 people at construction peak and can be looked at as an impetus for other solar research projects in California and helping to drive down the cost of solar energy.

Visit Project Page

554 Franklinville Road, Mullica Hill, NJ 08062

Education

2700

Financier-Owner

Visit Project Page

554 Franklinville Road, Mullica Hill, NJ 08062

Education

2700

Financier-Owner

BioStar acquired, owned and operated this New Jersey solar PV array from a project partner as a result of an exit. Our asset mangement team led customer communication, including monthly and quarterly production updates to ensure BioStar was meeting our requirements under the previously negotiated PPA. BioStar has since sold the portfolio in which this project resides.

Visit Project Page

1695 Hylton Road, Pennsauken Township, NJ 08110

Education

4003

Financier-Owner

Visit Project Page

1695 Hylton Road, Pennsauken Township, NJ 08110

Education

4003

Financier-Owner

Pennsauken School District Solar project completed construction and commenced operation in October of 2018. The project consisted of Solar PV, totaling 4MWdc, and roof replacements on 8 School buildings plus the Administrative Building in the Pennsauken School District. This project will generate over 4,500,000 kWh annually across all 9 properties for the next 25 years reducing the School District’s reliance on utility provided electricity.

Visit Project Page

771 S. Kulm Road, Othello, WA 99344

Farming

Developer

Visit Project Page

771 S. Kulm Road, Othello, WA 99344

Farming

Developer

In mid-2017, BioStar Organics, LLC formed a partnership with Perfect Blend, an Organic Fertilizer manufacturer and distributor located in Othello, WA to install and operate a facility that produces BioStar’s Super Six 6-0-0 Liquid Organic Fertilizer — utilizing BioStar’s patented technology. The facility will produce approximately 500,000 gallons of produce annually and has contracted to see all of the production for the next five years.

How It Works