Industry Resource Glossary

The primary commodity produced by the anaerobic digestion process is biogas. Biogas refers to the gas produced by the biological breakdown of organic matter in the absence of oxygen. Biogas originates from biogenic material and is a type of biofuel.

One type of biogas is produced by anaerobic digestion of biodegradable materials such as biomass, manure or sewage, municipal waste, green waste and energy crops. This type of biogas comprises primarily methane and carbon dioxide. BioStar cleans and processes this biogas, which can be used in any manner as natural gas, including heating, electricity and/or steam production. BioStar will design/build/ own / operate facilities based on a mutually agreeable GPA (Gas Purchase Agreement)

The process of anaerobic digestion naturally lowers the BOD (Biological Oxygen Demand) and COD (Chemical Oxygen Demand) in the effluent waste stream. Depending on the waste stream the typical BOD & COD reduction levels achieved are over 90% of the original levels and the TSS (Total Suspended Solids) levels of waste stream are typically reduced over 50%.

Depending on the waste stream and the amount of sewage treatment surcharges that are being assessed by the local municipality, food processors, in particular, can pay for the majority of a BioStar Systems facility by simply reducing or eliminating these surcharges.

BioStar facilities qualify for Greenhouse Gas emission offsets created by collecting, destroying and utilizing biogas produced by anaerobic treatment of animal manure, and managing waste using sustainable methods. Methane is a potent greenhouse gas and livestock manures have methane conversion and emission factors that vary by the manure management system, by livestock species/category, by manure characteristics, and by climatic conditions.

An ERU - Emission Reduction Unit - equals one ton of CO2 equivalent (CO2 is used as a value unit to measure greenhouse gases, for example, one metric ton of methane equals 21 metric tons of CO2).

The application of a BioStar anaerobic digestion system at a one-million hen egg production operation that uses a wet manure collection and lagoon storage system can generate up to 30,000 ERU's per year. The carbon credits from the fore-mentioned BioStar facility can generate $240,000 annually if sold at a price of $8.00 per ERU.

Carbon sequestration is one of the most promising means of reducing greenhouse emissions. According to the U.S. Department of Energy, even under the most optimistic scenarios for energy efficiency gains and the greater use of low- or no-carbon fuels, carbon sequestration will likely be essential if the world is to stabilize atmospheric concentrations of greenhouse gases at acceptable levels. BioStar's anaerobic digestion technology utilizes naturally-occurring bacteria and is a prime example of a commercially viable carbon sequestration technology.

Microbes and plants play substantial roles in the global cycling of carbon through the environment. The Office of Science's Biological and Environmental Research program continues to leverage new genomic DNA sequence information on microbes important to the global carbon cycle by characterizing key biochemical pathways or genetic regulatory networks in these microbes.

BioStar facilities generate biogas as part of the anaerobic digestion process. Fuel cell power plants can directly harness the methane in the biogas to fuel the power system in lieu of using natural gas, thus making the biogas a renewable energy source. Fuel cell systems can be 47% efficient in the generation of electrical power and up to 80% efficient overall in Combined Heat and Power ( CHP ) applications when the available waste heat is recovered and used. Typical fossil fuel-powered plants operate at about 35% mechanical to electrical conversion efficiency. Fuel cells represent a higher cost of electrical production; however, they include many additional environmental benefits.

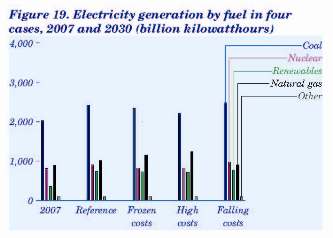

Natural gas, because of its clean-burning nature, has become a very popular fuel for the generation of electricity. In the 1970s and '80s, the choices for most electric utility generators were large coal or nuclear-powered plants; but, due to economic, environmental, and technological changes, natural gas has become the fuel of choice for new power plants. In fact, in 2009, 23,475 MW (megawatts) of new generation capacity was planned in the U.S. Of this, over 50%, or 12,334 MW, will be natural gas-fired additions. The graph below shows how, according to the Energy Information Administration (EIA), natural gas-fired electricity generation is expected to increase dramatically over the next 20 years, as all of the new capacity that is currently being constructed comes online.

There are many reasons for this increased reliance on natural gas to generate our electricity. While coal is the cheapest fossil fuel for generating electricity, it is also the dirtiest, releasing the highest levels of pollutants into the air. The electric generation industry, in fact, has traditionally been one of the most polluting industries in the United States. Regulations surrounding the emissions of power plants have forced these electric generators to come up with new methods of generating power while lessening environmental damage. New technology has allowed natural gas to play an increasingly important role in the clean generation of electricity. Click on the link for more information on the environmental benefits of natural gas, including its role as a clean energy source for the generation of electricity.

Source: EIA Annual Energy Outlook 2009 With Projections to 2030

Methane produced in BioStar facilities replaces methane derived from fossil fuels. The carbon in the biodegradable waste is part of a carbon cycle and, as such, the carbon released from the combustion of biogas can be thought of as having been removed by plants in the recent past, for instance within the last decade, but typically within the last growing season. If these plants are re-grown, as is the case with crops, it can be argued that the systems can be considered to be carbon neutral. This contrasts with carbon in fossil fuels that have been sequestered in the earth for many thousands of years.

Furthermore, if the putrescible waste feedstock to the digesters was landfilled, it would break down naturally and often anaerobically, in this case, the gas may escape into the atmosphere; and as methane is twenty-one times more potent as a greenhouse gas than carbon dioxide, this would be considered more harmful. In this way correctly engineered and knowledgeably applied anaerobic digestion systems can be considered to be sustainable and biogas considered being a renewable fuel.

The elimination of pathogens and E. coli is a primary benefit of the anaerobic digestion process.

Poultry and other livestock wastes are known to contain many pathogens that could potentially contaminate both surface water and groundwater resources. Alexander et al. (1968) tested 44 poultry litter samples for the presence of pathogens. They found 10 different species of Clostridium, 3 species of Salmonella, 2 species of Corynebacterium, 1 species of yeast, and 1 species of Mycobacterium(which is occasionally responsible for tuberculosis) in various litter samples. All of the litter samples contained Enterobacteriaceae (other than Salmonella), Bacillus spp., S taphylococcusspp., and Streptococcus spp. In Arkansas, the nation's leading poultry producing state, 90 percent of the surface water bodies (statewide) sampled recently by the Arkansas Department of Pollution Control and Ecology contained fecal coliform counts in excess of the primary contact standards.

BioStar's high-temperature anaerobic digestion process has been validated to provide the following destruction efficiencies:

- Cryptosporidium - Virtually complete destruction

- Giardia - Virtually complete destruction

- Salmonella - Virtually complete destruction

- Escherichia coli - 99.9999% reduction

- Fecal coliforms - 99.999% reduction

- Fecal streptococci - 99.999% reduction